injection moulding

one-stop-manufacturing

From your design to ready plastic solutions.

Our projects usually start with design for manufacturing and assessing objectively productibility and optimal raw material choices. Mould management requires special accuracy and care. We execute the mould acquisition process in co-operation with our customers and our trusted network of mould suppliers.

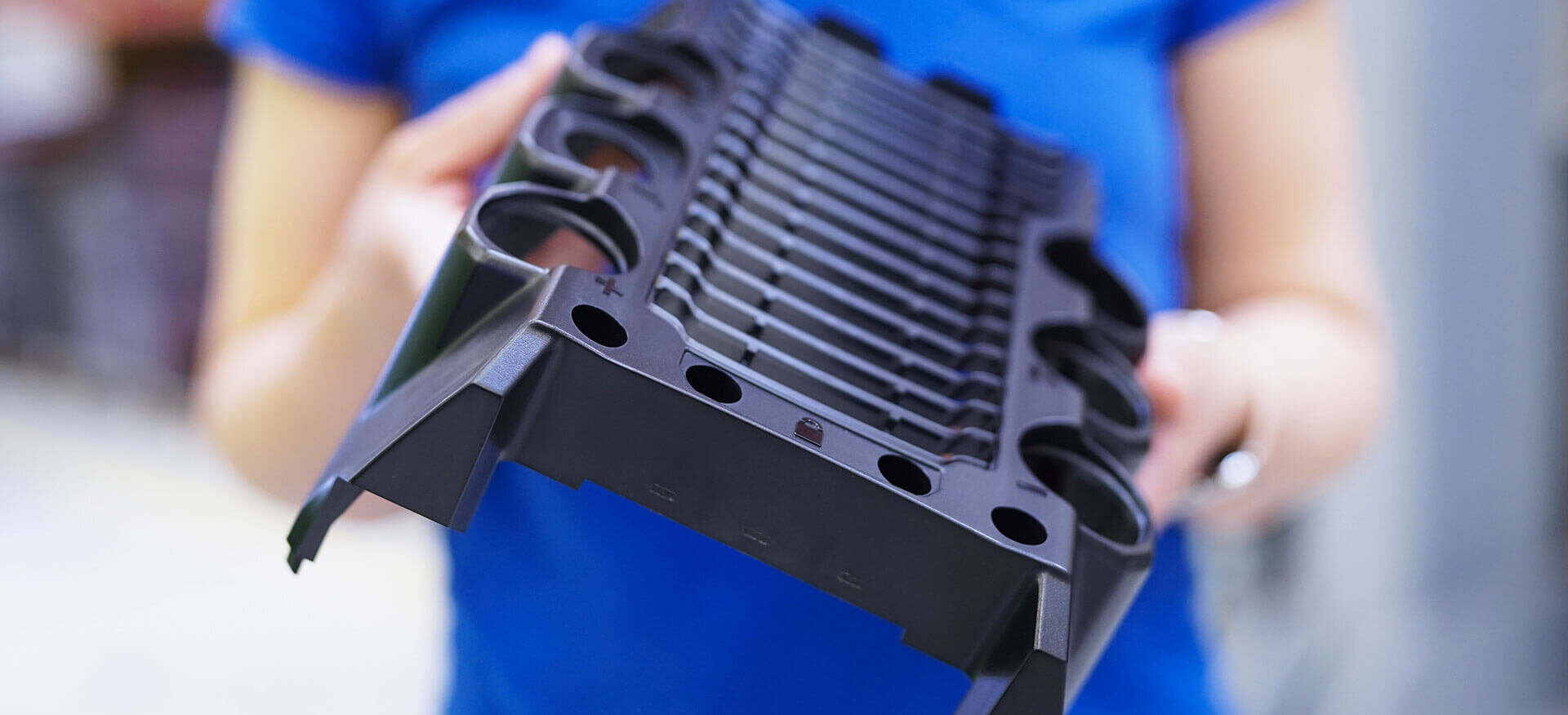

The designs become components and ready products with our state-of-the-art machinery that we invest in annually. Our injection moulding machinery covers clamping forces from 25 to 1,500 tonnes and has the ability to manufacture injection moulded parts weighing from less than 1 gram up to 8,000 grams.

Multi-component INJECTION moulding 2K / 3K

To be able to meet requirements of more complex designs, we offer multi-component injection moulding. We are capable of manufacturing two and three-component injection moulded products (2K and 3K).

Gas-assisted moulding

For production of larger plastic parts with complex designs and outstanding surface finishes, we offer gas assisted injection moulding. During the moulding process, pressurized nitrogen gas is injected to thicker areas of the part to press the plastic against the mould surface, leaving the plastic product hollow. In this way, thicker areas of the product can be turned into a shell-like thin-walled structure.